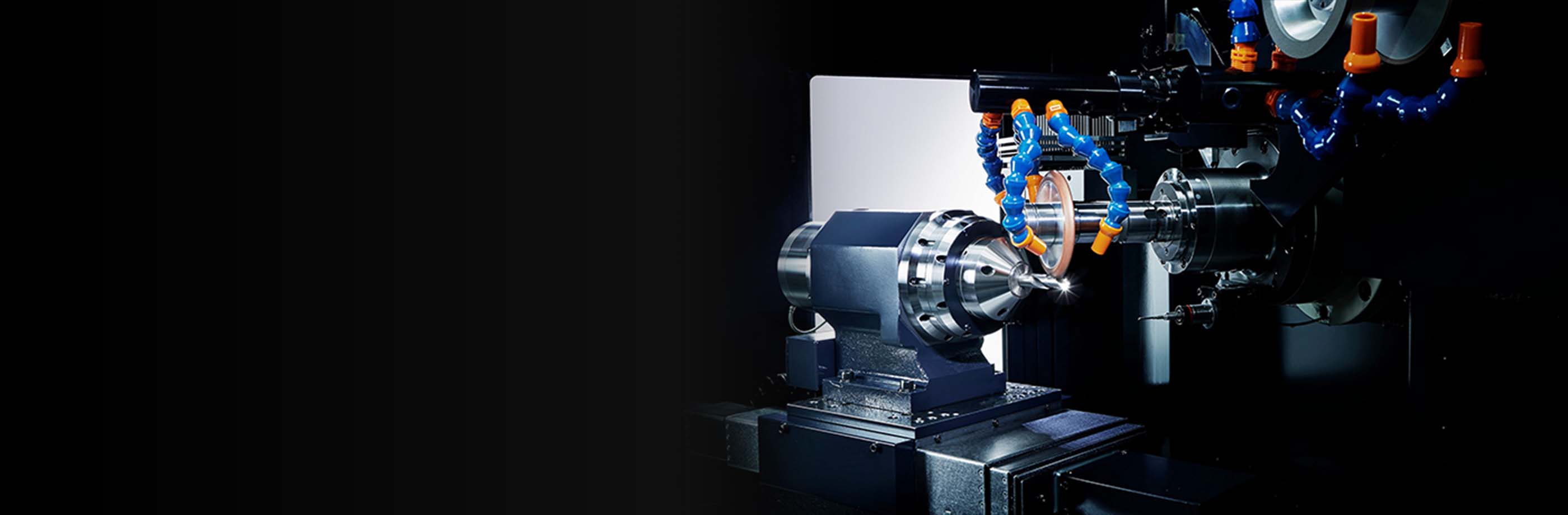

High-Precision CNC Tool & Cutter Grinder

Powerful and Compact Tool Grinder

with High Extensibility

High-precision, robust and compact structure.

Features / Specifications

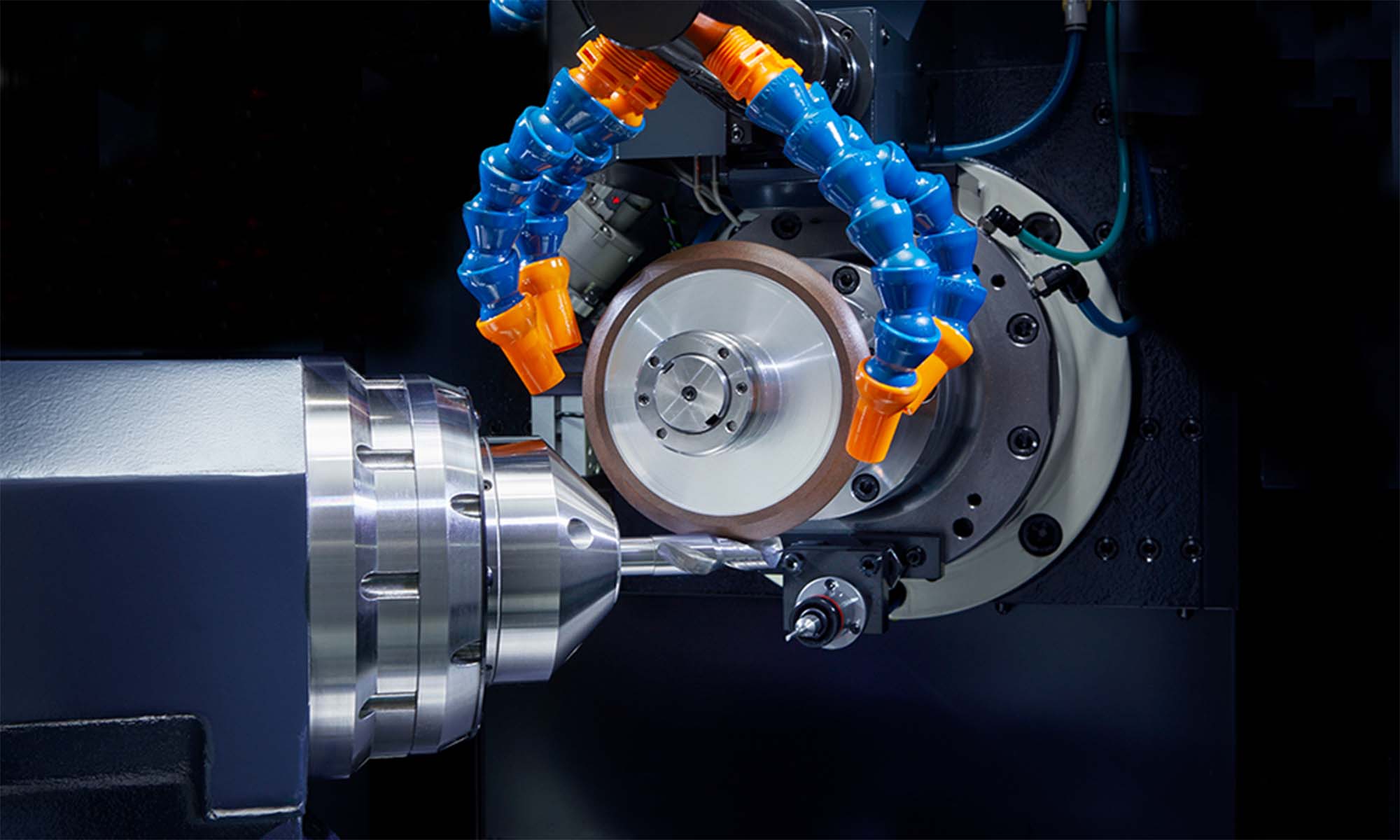

Superior grinding performance

Robust machine structure and powerful spindle ensure highly efficient grinding of large workpieces.

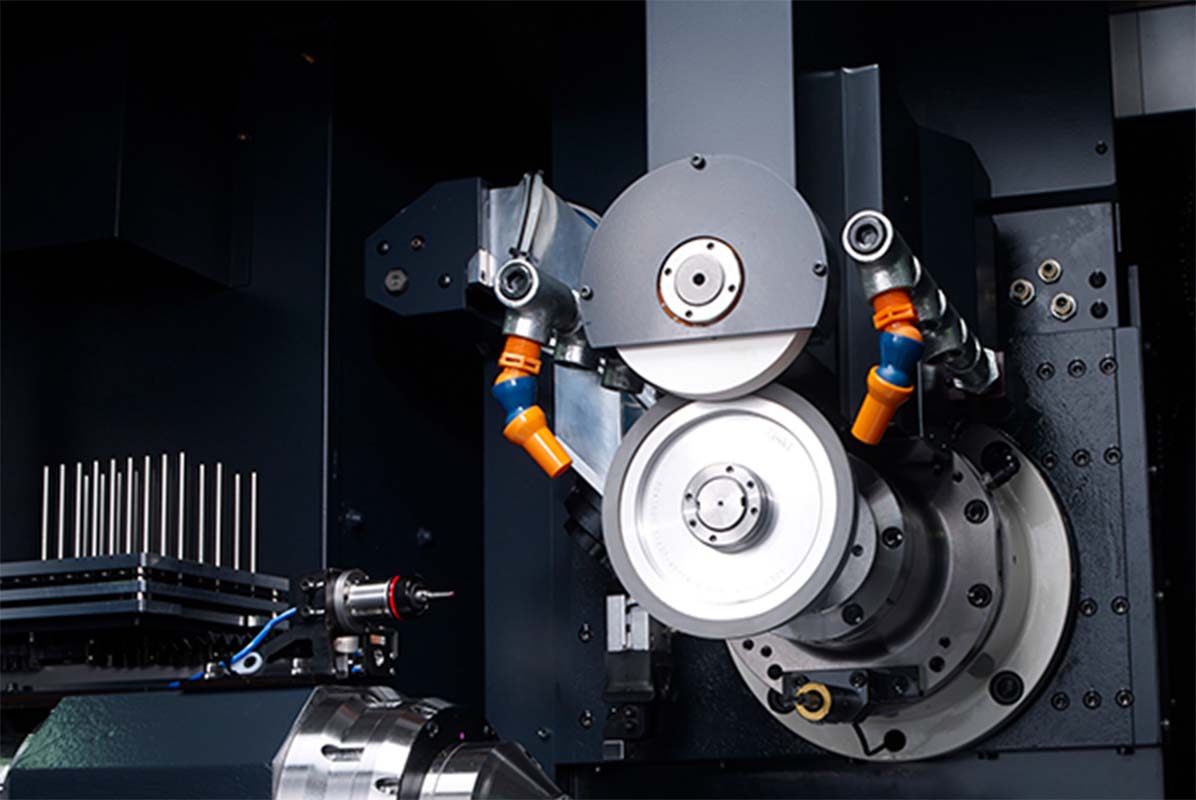

High extensibility

A variety of options can be selected for the improvement of productivity.

Grinding Wheel / Coolant Nozzle Changer “AWC3”

Fine Surface System Specialized for PCD Tool Grinding “FSS”

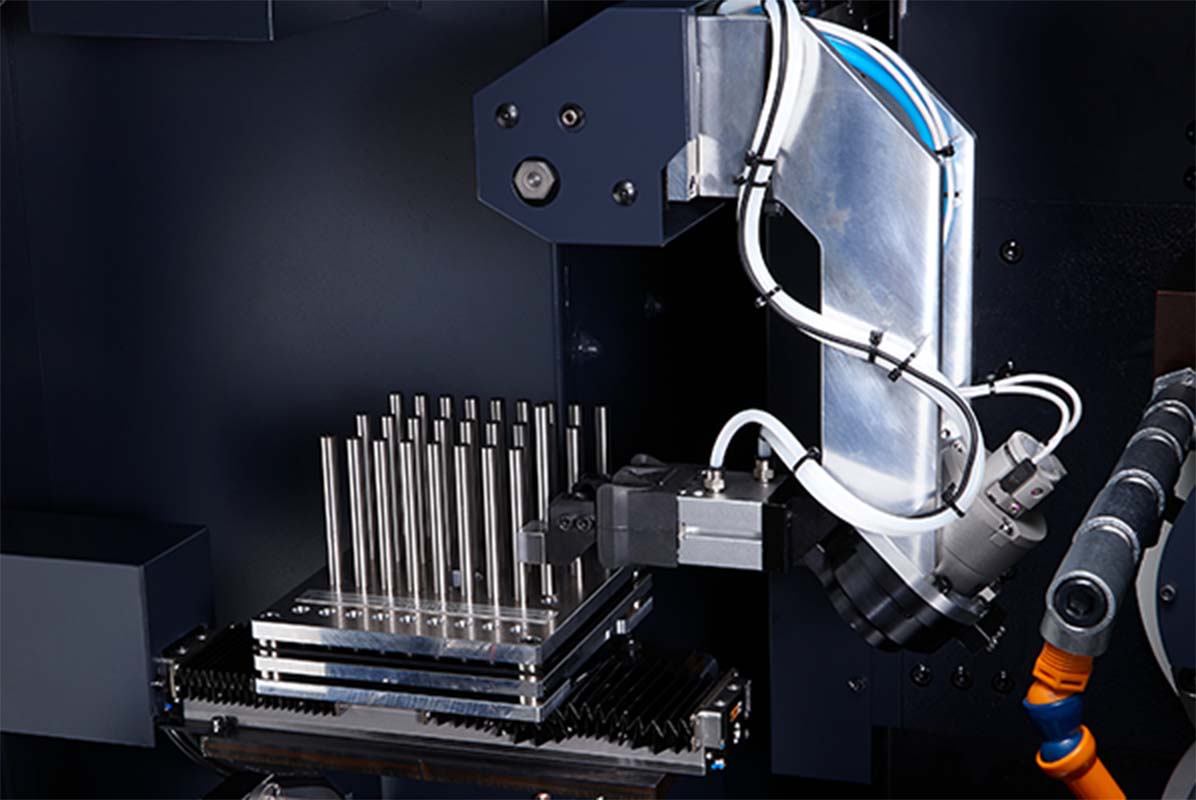

Automatic Workpiece Changer “Mini Loader”

Flexible Robot Loading System “ROBOX”

Maximum Tool Size for Grinding

Overall tool length

max.200mm

Tool diameter

max.φ150mm

Grinding Spindle

Spindle nose taper

HSK-A50

Max. output power

22.0kW

Spindle speed

500~8000min-1

Work Head

Spindle nose taper

ISO No.40 Manual clamp

Spindle speed

400min-1